Water And Wastewater Treatment

Our company provides water and wastewater treatment solutions designed to maintain clean water quality while ensuring effective and environmentally friendly wastewater management. Utilizing advanced technology and the expertise of a professional team, we are committed to delivering the best results in every stage, from initial filtration to final purification.

Cooling Tower

Key component :

- Construction: Cooling towers are typically made from corrosion-resistant materials such as fiberglass, concrete, or metal. Their designs vary, ranging from open to closed types, depending on the application and efficiency needs.

- Water Flow System: Hot water from the cooling system or industrial process is directed to the cooling tower, where it is distributed over a larger surface area to maximize contact with the air.

- Ventilation System: Outside air is drawn or blown into the cooling tower, interacting with the flowing water, causing some of the water to evaporate and removing heat.

Types of Cooling Towers:

- Natural Draft: Utilizes natural air flow to cool the water.

- Forced Draft: Uses fans to push air into the tower.

- Induced Draft: Uses fans at the top to pull air through the unit.

Cooling towers are commonly used in power plants, chemical factories, HVAC (heating, ventilation, and air conditioning) systems, and other cooling systems.

Advantages:

- Increases cooling system efficiency.

- Reduces water consumption through recirculation.

- Allows equipment to operate at optimal temperatures.With its crucial role in temperature control and energy efficiency, the cooling tower is an essential component in many modern industries.

FRP Tank

FRP tanks, or fiberglass-reinforced plastic tanks, are storage containers made from fiberglass reinforced with plastic resin. These tanks are known for their high durability and strength, as well as their ability to resist corrosion, making them ideal for storing a variety of liquids, including water, chemicals, and oil.

Key features of FRP tanks include:

- Lightweight and Strong: Despite being made from a lightweight material, FRP tanks have excellent strength and can withstand high pressures.

- Corrosion Resistance: FRP tanks will not rust or corrode from chemicals, making them ideal for storing aggressive liquids.

- Thermal Insulation: The fiberglass material provides good insulation properties, helping to maintain the temperature of the liquids inside the tank.

- Design Flexibility: FRP tanks can be manufactured in various shapes and sizes to meet specific needs, offering great flexibility for different applications.

- Low Maintenance Costs: Due to their resistance to corrosion and damage, these tanks require relatively low maintenance costs.

Mild Steel Tank

Mild steel tanks are storage containers made from mild steel, a type of carbon steel with a low carbon content that provides excellent ductility and weldability. These tanks are widely used for various applications due to their strength, durability, and cost-effectiveness.

Key features of mild steel tanks:

- Strength and Durability: Mild steel tanks are known for their structural integrity and ability to withstand significant pressure and stress, making them suitable for storing liquids and other materials.

- Weldability: The low carbon content in mild steel allows for easy welding and fabrication, enabling the creation of tanks in various shapes and sizes to meet specific needs.

- Cost-Effective: Compared to other materials, mild steel is often more affordable, making it a popular choice for various industries.

- Versatile Applications: Mild steel tanks can be used for a wide range of applications, including water storage, fuel storage, chemical processing, and more.

- Surface Treatment Options: Mild steel tanks can be coated or painted to enhance their corrosion resistance and protect against environmental factors, extending their lifespan.

- Maintenance Requirements: Regular maintenance, including inspections and protective coatings, is necessary to prevent rust and extend the tank’s service life.

Mild steel tanks are commonly used in industries such as agriculture, construction, manufacturing, and water treatment, providing reliable and efficient storage solutions.

Mixer Chemical Tank

A Mixer Chemical Tank is an industrial device designed for mixing various types of chemicals in large volumes. Typically made from corrosion-resistant materials such as stainless steel or industrial-grade plastics, this tank features an efficient mixing system, such as agitators or propellers, to ensure uniformity of the mixture.

Key features of a Mixer Chemical Tank include:

- Variable Capacity: Available in various sizes to meet different production needs.

- Mixing System: Designed to mix materials quickly and thoroughly, reducing processing time.

- Temperature and Pressure Control: Some models come equipped with sensors and controls to monitor conditions during mixing.

- Ease of Cleaning: A design that allows easy access for cleaning, crucial for preventing cross-contamination between batches.

- Safety Features: Equipped with safety systems to prevent leaks or hazardous reactions.

Mixer Chemical Tanks are widely used in the chemical, pharmaceutical, food and beverage, and cosmetic industries, where precise mixing of ingredients is essential for the quality of the final product.

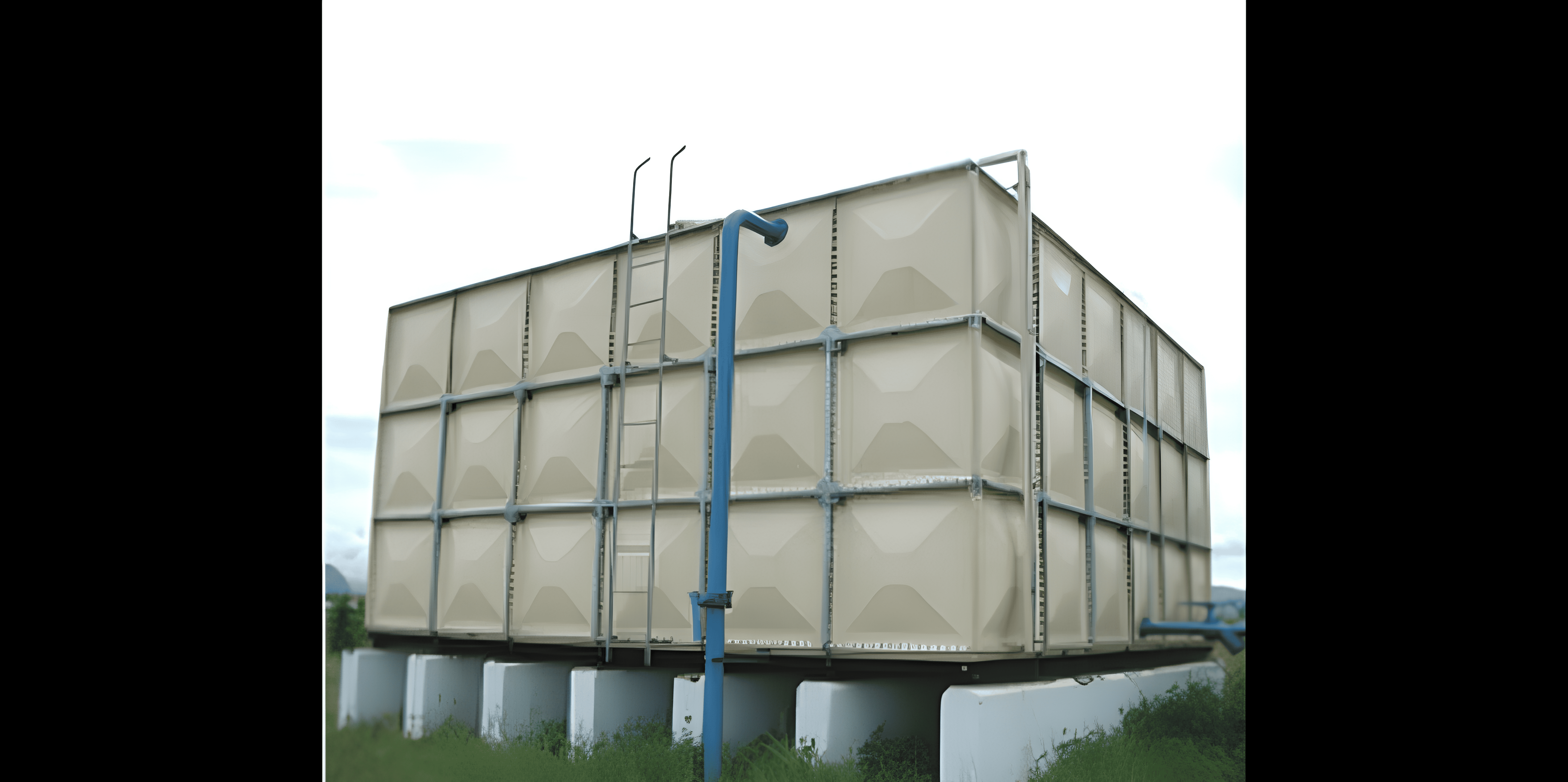

Panel Tank

A panel tank is a modular storage solution commonly used in various industries for the containment of liquids, including water, chemicals, and other substances. Constructed from durable materials such as fiberglass, stainless steel, or polyethylene, panel tanks are designed for both above-ground and underground applications.

Key Features of Panel Tanks:

- Modular Design: Composed of interlocking panels that can be easily assembled or disassembled, allowing for customization in size and shape according to specific needs.

- Durability: Built to withstand environmental factors and corrosion, ensuring long-lasting performance and minimal maintenance.

- Flexibility: Suitable for a wide range of applications, including water storage, wastewater treatment, and chemical storage.

- Easy Installation: The panel design allows for quick and efficient installation, reducing downtime in operations.

- Cost-Effective: Typically more affordable than traditional tank options, especially for large-scale projects, due to the ease of transportation and installation.

- Safety Features: Often designed with built-in safety measures, such as overflow prevention and secure sealing, to protect against leaks and spills.

Panel tanks are ideal for businesses looking for reliable and efficient storage solutions that can be tailored to meet specific operational requirements.

Pretreatment System

A pretreatment system is a crucial component in various industrial processes, designed to prepare raw materials or influent for subsequent treatment or processing stages. This system is commonly used in water treatment, wastewater management, and chemical processing to enhance efficiency and effectiveness.

Key Features of a Pretreatment System:

- Purpose: The primary goal is to remove contaminants, sediments, and unwanted materials from raw influents, ensuring that the feedstock meets the required specifications for further treatment.

- Processes Involved: Depending on the application, pretreatment may include physical processes (such as filtration and sedimentation), chemical treatments (like coagulation and flocculation), or biological methods (aerobic or anaerobic treatments).

- Customization: Pretreatment systems can be tailored to specific needs, accommodating different types of influents and contaminants. This flexibility ensures optimal performance for a wide range of applications.

- Efficiency: By removing problematic substances before they reach the main treatment process, pretreatment systems improve overall efficiency, reduce operational costs, and prolong the lifespan of downstream equipment.

- Regulatory Compliance: Implementing an effective pretreatment system helps ensure that discharged effluents comply with environmental regulations, reducing the risk of fines and promoting sustainability.

- Monitoring and Control: Many modern pretreatment systems are equipped with monitoring and control technologies that provide real-time data on system performance and influent quality, enabling proactive management.

Pretreatment systems play a vital role in enhancing the effectiveness of industrial processes, ensuring that subsequent treatments are more efficient and effective while minimizing environmental impact.

Reverse Osmosis Membrane

A pretreatment system is a crucial component in various industrial processes, designed to prepare raw materials or influent for subsequent treatment or processing stages. This system is commonly used in water treatment, wastewater management, and chemical processing to enhance efficiency and effectiveness.

Key Features of a Pretreatment System:

- Purpose: The primary goal is to remove contaminants, sediments, and unwanted materials from raw influents, ensuring that the feedstock meets the required specifications for further treatment.

- Processes Involved: Depending on the application, pretreatment may include physical processes (such as filtration and sedimentation), chemical treatments (like coagulation and flocculation), or biological methods (aerobic or anaerobic treatments).

- Customization: Pretreatment systems can be tailored to specific needs, accommodating different types of influents and contaminants. This flexibility ensures optimal performance for a wide range of applications.

- Efficiency: By removing problematic substances before they reach the main treatment process, pretreatment systems improve overall efficiency, reduce operational costs, and prolong the lifespan of downstream equipment.

- Regulatory Compliance: Implementing an effective pretreatment system helps ensure that discharged effluents comply with environmental regulations, reducing the risk of fines and promoting sustainability.

- Monitoring and Control: Many modern pretreatment systems are equipped with monitoring and control technologies that provide real-time data on system performance and influent quality, enabling proactive management.

Pretreatment systems play a vital role in enhancing the effectiveness of industrial processes, ensuring that subsequent treatments are more efficient and effective while minimizing environmental impact.

Reverse Osmosis (RO) membranes, specifically SWRO (Seawater Reverse Osmosis) and BWRO (Brackish Water Reverse Osmosis), are critical components in water purification systems designed to remove contaminants from seawater and brackish water, respectively.

SWRO (Seawater Reverse Osmosis)

- Purpose: SWRO membranes are designed to desalinate seawater, making it suitable for drinking and agricultural use by effectively removing salts and other impurities.

- Material: Typically made from thin-film composite materials, these membranes exhibit high salt rejection rates and durability under high-pressure conditions.

- Performance: SWRO systems can achieve salt rejection rates of over 99%, significantly lowering the salinity of the water.

- Applications: Commonly used in coastal regions and islands where freshwater resources are limited, SWRO systems are essential for providing potable water and supporting local agriculture.

BWRO (Brackish Water Reverse Osmosis)

- Purpose: BWRO membranes target brackish water sources, which contain lower salinity levels than seawater but still require treatment for safe consumption.

- Material: Similar to SWRO, BWRO membranes are constructed from advanced composite materials that allow for effective separation of dissolved solids while maintaining good permeability.

- Performance: BWRO systems typically reject 95-98% of dissolved salts and contaminants, making them effective for producing clean drinking water.

- Applications: Widely used in agricultural irrigation, industrial processes, and municipal water supply systems, BWRO is a versatile solution for regions with brackish water resources.

Common Features of RO Membranes

- High Efficiency: Both SWRO and BWRO membranes are known for their high water recovery rates and low energy consumption compared to traditional desalination methods.

- Modular Design: These systems can be scaled up or down depending on the specific water treatment needs and capacities.

- Maintenance: Regular cleaning and monitoring are essential to maintain membrane performance and longevity.

In summary, SWRO and BWRO membranes are vital technologies in addressing water scarcity issues by converting saline water sources into safe and usable freshwater. Their efficiency and adaptability make them indispensable in modern water treatment solutions.